Fully Automatic Revolution: Chili Powder Sterilization Machine for High-Efficiency Processing

Introduction

Our company leverages cutting-edge technologies from Cellencor and IMS to develop a state-of-the-art microwave sterilization technique. By drawing inspiration from the advanced methodologies employed by Cellencor and IMS, we have successfully integrated their innovative approaches into our manufacturing process. This collaborative effort ensures that our microwave sterilization technology meets the highest industry standards, providing an effective and efficient solution for eliminating harmful microorganisms. Through continuous refinement and adaptation of these proven techniques, our company remains at the forefront of technological advancements in the field, delivering products that prioritize both safety and quality.

Evolution of Chili Powder Sterilization Technologies

Tracing back through history, various methods have been employed for chili powder sterilization. As the food processing industry evolved, so did the needs and standards. This section explores the journey from conventional to contemporary sterilization technologies, highlighting the demand for advanced solutions and the subsequent development of fully automatic systems.

Technological Advancements in Chili Powder Sterilization Machines

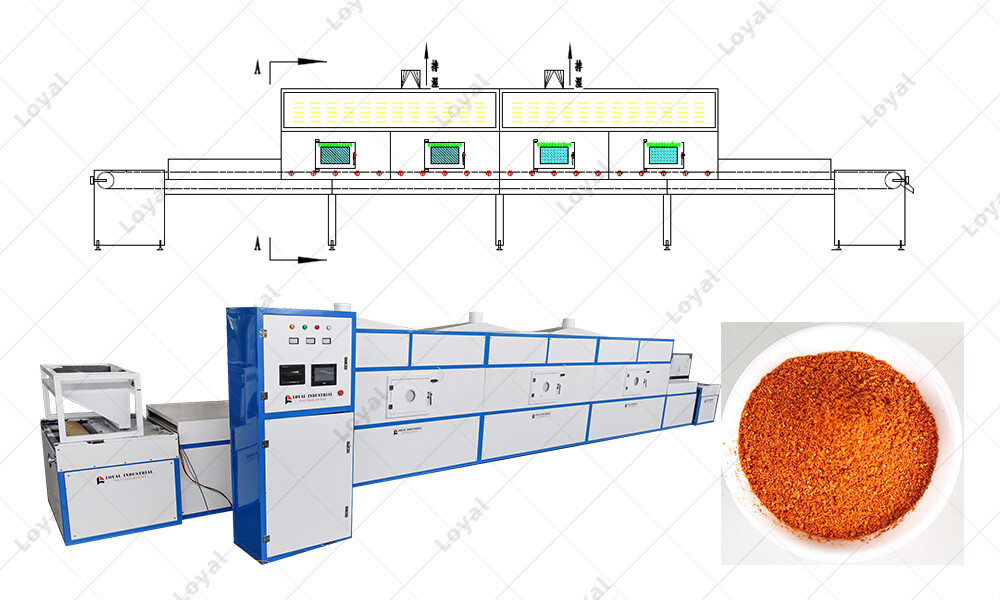

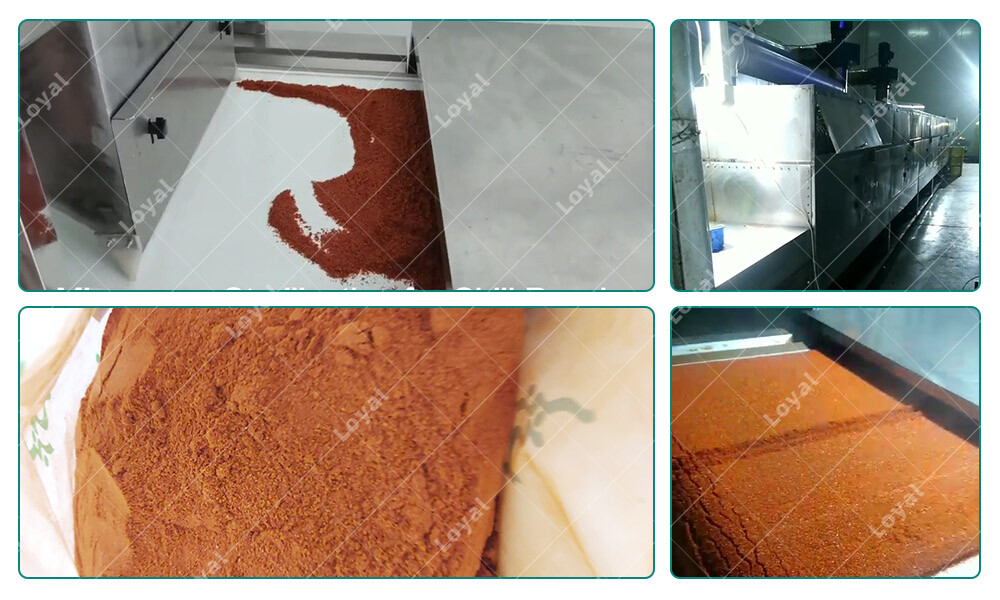

A closer look at the operational features of fully automatic systems reveals a realm of technological advancements. The Fully Automatic Chili Powder Sterilization Machine incorporates cutting-edge technology to elevate the efficiency of chili powder sterilization. This section underscores the machine's benefits, positioning it as a superior alternative to traditional methods.

Precision and Quality in Sterilization

The heart of any sterilization process lies in precision and maintaining product quality. Here, we delve into how the fully automatic system ensures unparalleled precision, exploring its impact on the quality of chili powder products. The discussion emphasizes the technological edge that enables the system to surpass the integrity maintenance of traditional methods.

Integration into Chili Powder Processing

Seamless integration is a hallmark of efficiency. Examining the Fully Automatic Chili Powder Sterilization Machine reveals its adaptability across various stages of chili powder manufacturing. Real-world case studies and applications exemplify the machine's prowess in increasing efficiency and productivity, solidifying its position in the processing chain.

Economic and Environmental Advantages

Beyond technological sophistication, the article analyzes the economic benefits and cost efficiency that the fully automatic system brings to manufacturers. Simultaneously, it shines a light on the environmental sustainability aspects, showcasing reduced energy consumption and waste compared to conventional sterilization methods.

Technological Innovations and Future Trends

Innovation is the lifeblood of progress. This section explores the ongoing technological innovations in chili powder sterilization, hinting at the future trends that will shape the landscape. The evolution of fully automatic systems to meet emerging industry demands is discussed, offering insights into the future of chili powder processing.

Regulatory Compliance and Safety

A reliable sterilization system must adhere to rigorous standards. The article investigates the regulatory landscape, certifications, and safety measures integrated into fully automatic systems. Emphasis is placed on how the industry aligns with quality and safety standards, ensuring a secure environment for chili powder production.

Case Studies: Success Stories with Fully Automatic Chili Powder Sterilization

Real-world success stories become the focal point in this section, illustrating how manufacturers have achieved efficiency and productivity goals through the adoption of fully automatic systems. The cases presented serve as compelling evidence of the machine's impact on the success of chili powder manufacturing.

Conclusion

In summary, this article provides an in-depth exploration of the revolutionary capabilities of the Fully Automatic Chili Powder Sterilization Machine. From historical perspectives to future trends, from economic benefits to environmental sustainability, the machine emerges as a game-changer in the realm of chili powder processing. The FAQs section aims to address common inquiries, ensuring a comprehensive understanding of the machine's significance in the food processing industry. Manufacturers are encouraged to embark on this high-efficiency journey for elevated productivity and excellence.

Common Questions about Chili Powder Sterilization Machine

Q1: How does the Fully Automatic Chili Powder Sterilization Machine differ from traditional methods?

The Fully Automatic Chili Powder Sterilization Machine revolutionizes the sterilization process. Unlike traditional methods, which may involve manual labor and lack precision, this automated system utilizes advanced technology for a seamless and precise process. Its efficiency is unparalleled, ensuring a consistent and high-quality output.

Q2: What are the key operational features of the Fully Automatic Chili Powder Sterilization Machine?

This section dives into the operational intricacies of the machine, emphasizing its advanced features. The use of cutting-edge technology, precision control mechanisms, and adaptability across various processing stages are highlighted. The aim is to elucidate how these features contribute to the machine's efficiency.

Q3: What economic benefits and cost efficiencies does the Fully Automatic Chili Powder Sterilization Machine offer?

Economics play a crucial role in technology adoption. This part of the FAQs delves into the economic advantages, emphasizing cost efficiency for manufacturers. The analysis includes a thorough examination of how the machine contributes to overall operational excellence and resource optimization.

Q4: How does the Fully Automatic Chili Powder Sterilization Machine align with environmental sustainability goals?

Environmental sustainability is a growing concern. This question explores the eco-friendly aspects of the fully automatic system, including reduced energy consumption and waste compared to traditional sterilization methods. The discussion emphasizes how the technology aligns with sustainability goals in food processing.

Q5: What ongoing technological innovations can we expect in chili powder sterilization?

The section on future trends addresses the dynamic nature of the industry. Ongoing technological innovations and advancements in chili powder sterilization are explored, offering insights into the evolving landscape and how the Fully Automatic Chili Powder Sterilization Machine is adapting to meet emerging industry demands.

Q6: How does the Fully Automatic Chili Powder Sterilization Machine comply with regulatory standards and ensure safety?

This question navigates through the regulatory landscape, certifications, and safety measures integrated into the fully automatic system. The aim is to assure manufacturers and stakeholders of the machine's adherence to quality and safety standards, creating a secure and compliant environment for chili powder production.

Q7: Are there any notable success stories with the adoption of the Fully Automatic Chili Powder Sterilization Machine?

Real-world case studies take the spotlight in this section, showcasing notable success stories from manufacturers who have embraced the fully automatic system. These stories serve as compelling evidence of the positive impact on efficiency, productivity, and overall success in chili powder manufacturing.