Unlock The Secrets Of Efficient Stainless steel Industry biscuit making machine Manufacturing

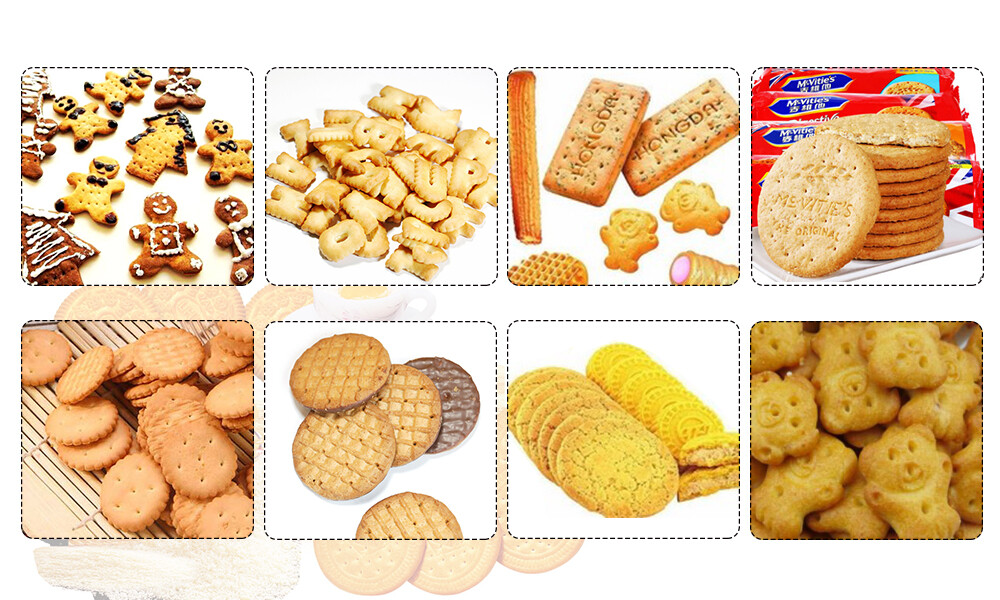

This Stainless steel Industry biscuit making machine can produce various biscuit types: soft, buttery biscuits that melt in your mouth, crunchy hard biscuits perfect for dunking, biscuit with rich, creamy fillings, and a variety of crispy crackers. In any type of laminated biscuit, there are the following process phases: the meticulous preparation of the dough, its fermentation or stasis (in the case of some crackers or semi-hard biscuits), the careful formation of the dough, its sheeting (in the case of some recipes), the precise reduction of the thickness of the final sheet and subsequent cutting into perfectly uniform shapes, baking in a hot oven to achieve the ideal golden-brown color and texture, and finally cooling before packaging to ensure freshness and crispiness.

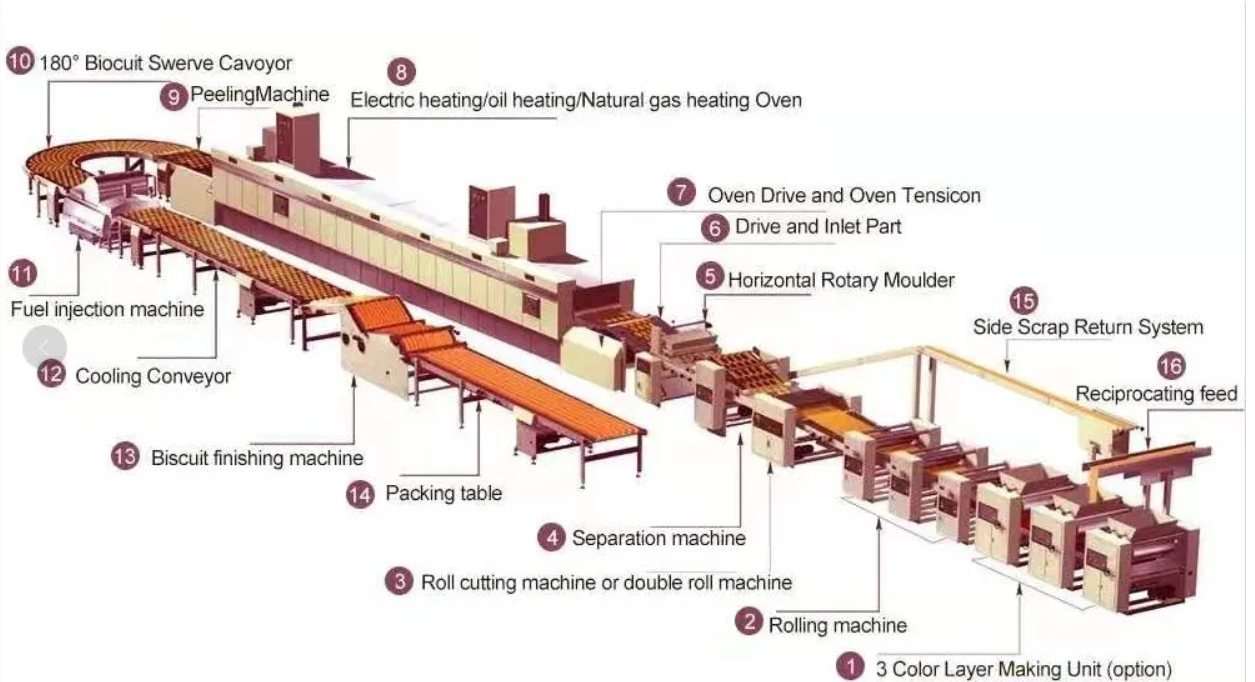

The biscuit production line is composed of cookie forming machine, electric baking oven, oil spraying machine, turning machine, cooling line, cookie finishing machine, packing table and so on. The whole line is controlled by CPU module, back hung motor drive, compact structure and high degree of automation. The machine can also produce various flavors of high quality cookies, such as cream, jam, etc.

Biscuit Maker (Cookie Pastry Machine, is a forming machine that can produce a variety of unique fancy snacks and cookie blanks by extrusion of dough.The machine has a variety of molds and can produce dozens of fancy cookies, and users can adjust and choose according to their needs. Formed fancy Desserts and cookies have unique shapes, clear patterns and beautiful shapes. The shaped cookies by this machine can be baked in a hot air rotary furnace and a tunnel furnace.

Description Of Biscuit Production Line

This automatic biscuit production line,a result of the meticulous digestion and absorption of advanced Japanese technology, has been meticulously developed from the latest cutting-edge equipment design. It features a sleek, compact yet robust structure, designed to withstand rigorous daily operations while maintaining a high degree of automation. The line seamlessly handles every intricate step of the biscuit-making process, from the initial feed rolling, where dough is evenly distributed, to the precise forming stage, where biscuits take shape, followed by efficient waste recycling, thorough drying, delicate coating, and final cooling, all completed in one seamless continuous operation. The company offers users access to hundreds of different molds, each intricately designed to create various shapes and sizes, along with dozens of carefully crafted formulas, allowing for versatile and customizable production capabilities. By simply changing the mold and adjusting the process recipe, manufacturers can effortlessly produce a wide range of market-popular high-end cookies, each with unique textures, rich flavors, and appealing appearances, catering to diverse consumer preferences.

Biscuit Forming Process

DOUGH MIXING MACHINE →SOFT&HARD BISCUIT SHAPING MACHINE → TUNNEL BELT OVEN→ SPRAYING MACHINES →COOLER

1.Flour mixer: mixing the flour, eggs, sugar and seasonings

2.Hard biscuit form machine/ soft biscuit form machine: roller cutting and roller stamping, form the biscuit

3.Oven: baking the biscuit

4.Oil sprayer: spraying the oil

5.Cooling conveyor: cooling and conveying

6.Packaging machine: packaging the biscuit

The cookie production process is a precise manufacturing procedure that integrates food science with mechanical automation. The entire production line, from raw material mixing to finished product packaging, is meticulously designed to ensure the product achieves optimal taste and quality standards.

The production process begins with the flour mixing stage, which is carried out by professional mixers. The mixer combines high-quality wheat flour, fresh eggs, fine sugar, and various seasonings according to strict proportions. Through the rotational movement of dual stirring paddles, all ingredients are thoroughly blended. Modern mixing equipment typically includes temperature control systems that maintain the mixture's temperature within an ideal range, ensuring the dough has the perfect elasticity and consistency. After 10-15 minutes of thorough mixing, the uniform dough is automatically conveyed to the next stage.

The shaping process varies depending on the type of product. For hard biscuits, a roller cutting machine is used, where the dough is pressed through multiple rollers to form a uniformly thick sheet, which is then cut using specially designed molds. Soft biscuits, on the other hand, are made using a roller imprinting machine, where the dough is shaped on rollers with engraved patterns, creating beautiful three-dimensional designs on the surface of the biscuits. During the shaping process, an advanced visual inspection system continuously monitors the shape integrity of each biscuit, automatically removing any substandard semi-finished products.

Baking is the critical step that determines the final quality of the biscuits. Tunnel ovens are designed with multiple temperature zones, and the biscuits are conveyed through preheating, baking, and coloring sections. The preheating zone maintains temperatures between 120-150°C to initially set the internal structure of the biscuits; the baking zone raises the temperature to 180-220°C to promote the Maillard reaction, producing unique aromas and colors; finally, the coloring zone precisely controls the surface color. Modern ovens are equipped with hot air circulation systems to ensure uniform temperature distribution within the oven, with a temperature difference not exceeding ±3°C.

After baking, the cookies undergo an oil spraying process that imparts a unique flavor and sheen. The automatic oil spraying system uses high-pressure atomization technology to evenly spray edible oil on the cookie surface, with the amount of oil controlled by a precise metering pump to be between 0.5 and 1.2 grams per cookie. Some premium products also add flavored oils or nutritional enhancers at this stage to increase their added value.

The cooling process is equally crucial, as freshly baked cookies need to pass through a cooling conveyor belt that is 15 to 20 meters long. This specially designed conveyor system is equipped with temperature and humidity control devices, using a combination of natural convection and forced ventilation to gradually reduce the cookie temperature from around 80°C to room temperature. During this process, moisture inside the cookies continues to distribute evenly, ultimately achieving the ideal crispy texture. At the end of the conveyor belt, a metal detector performs the final quality check.

Parameter Of Biscuit Production Line

item | Capacity | Heating type |

LY-280 | 100kg/h | Electricity, Gas, Diesel |

LY-400 | 150-200kg/h | Electricity, Gas, Diesel |

LY-600 | 400-500kg/h | Electricity, Gas, Diesel |

LY-800 | 600-900kg/h | Electricity, Gas, Diesel |

LY-1000 | 1000kg/h | Electricity, Gas, Diesel |

LY-2000 | 2000kg/h | Electricity, Gas, Diesel |

The Detail Descriptions Of Biscuit Production Line

No. | Item | Detail descriptions |

| 1 | Raw materials | -Wheat flour, sugar, eggs, vegetable oil/palm oil, milk powder, leavening agents, flavors (customizable formulations for different biscuit types) |

| 2 | Consumption | -Power consumption: 25-30% lower than conventional lines - Automated systems reduce labor requirements by 40% - Energy recovery system for heat reuse |

| 3 | Capacity | -Multiple configuration options: - Small scale: 100kg/h<br- Medium scale: 150-200kg/h, 300-350kg/h, 400-500kg/h - Large scale: 600-900kg/h, 1000kg/h, 2000kg/h |

| 4 | Machine material | -Food-grade 304 stainless steel (contact parts) - Reinforced steel frame - Corrosion-resistant surface treatment |

| 5 | Products | - Hard biscuits (crackers, digestive) - Soft biscuits (shortbread, cookies) - Sandwich biscuits (cream-filled) - Special shapes (custom molds available) |

Key Features:

Multi-format capability: Quick changeover between product types

Hygienic design: Complies with international food safety standards

Scalable operation: Capacity can be upgraded with additional modules

Precision control: ±1% weight accuracy for consistent product quality

This specification sheet clearly presents your production line's capabilities while highlighting its versatility across different biscuit types and production scales. The structured format makes it easy for potential customers to understand the machine's key parameters and benefits.

Advantage

Feature | 1.a variety of different molds and different formulas. |

2.good cooling effect | |

3.big output(from 100kg/h to 2000kg/h) | |

4.PLC screen touch control | |

5.easy operation | |

6.smooth work |

1.A complete soft and hard biscuit production line , which can make all kinds of biscuits of various shapes, just change the mold.

●Soft & Hard Biscuits: Adjust dough consistency, baking time, and temperature to produce chewy, crispy, or layered biscuits.

●Multiple Shapes & Designs: Simply change the mold to switch between round, square, animal-shaped, or custom-designed biscuits.

●Wide Recipe Compatibility: Works with various dough types, including sugar-based, savory, gluten-free, and high-fiber recipes.

2.The biscuit production line can be customized according to the customer's workshop or biscuit making technical requirement

●Adaptable Layout: The machine can be adjusted in size, conveyor length, and configuration to fit small, medium, or large workshops.

●Tailored Technical Specifications: Customize baking time, temperature zones, and cooling speed based on your biscuit type.

●Optional Add-ons: Additional modules like chocolate coating, cream filling, or double-layer baking can be integrated.

3.Have different heating sources for your operation (Electric, gas, Diesel oil)

●Electric Heating: Best for stable temperature control, suitable for indoor factories with electricity supply.

●Gas Heating: Cost-effective for large-scale production with consistent heat distribution.

●Diesel Oil Heating: Ideal for areas with limited gas or electricity access, providing high thermal efficiency.

4.It is full automatic, advanced technology, easy to operation, high quality,save energy & labor, reasonable price to win customer reply and reputation.

●PLC Touch Screen Control: Easy-to-use interface for adjusting speed, temperature, and baking time.

●Energy-Saving Design: Optimized heat circulation and insulation reduce power consumption.

●Minimal Labor Requirement: Automated feeding, forming, baking, and packaging reduce manual work.

●Smooth & Stable Performance: Precision-engineered components ensure low maintenance and long service life

Sample

Theindustrial automatic biscuit production line produces high-quality soft and hard biscuits, from material mixing to finished products, all in one go, with an automatic waste recycling system. Our biscuit production line can make soft biscuits, hard biscuits, butter biscuits, sandwich biscuits, soda biscuits, animal biscuits, vegetable biscuits, cream biscuits, etc. The biscuit production line is designed according to the requirements of each customer, such as stepless speed regulation, fast and slow, automatic temperature control, automatic power-off alarm. The biscuit making machine oven heating type can be gas, electric, etc.

Innovative directions and market opportunities for biscuit production lines

- Green and sustainable production

- Energy efficiency improvement:The production line is equipped with solar panels to reduce dependence on the power grid.

- Adaptation to eco-friendly materials:Upgrade low-waste processes

- Policy-driven: Europe's 'Green Deal' and China's 'Dual Carbon' goals will push for equipment upgrades, and production lines that fail to meet energy efficiency certifications may be phased out.

- Intelligentization and digitalization deeply penetrate

- IoT sensors monitor equipment vibrations and temperature anomalies, allowing for early replacement of parts and reducing downtime losses.

- The AI camera detects color and shape defects in cookies, such as cracks and burning, with an accuracy exceeding 99%, reducing the cost of manual spot checks.

- Adjust baking temperature and time dynamically using sensors (such as automatically optimizing parameters based on dough moisture content)

- Emerging Market Localization Needs

- Southeast Asia and Africa

• Climate Adaptability: Develop moisture-resistant and heat-tolerant equipment (e.g., enhanced packaging sealing for the Indian monsoon season).

• Miniaturized Production Lines: Introduce affordable models with capacities of 1-2 tons per hour for family workshops or community factories.

- Health Snack Trend

• Functional Cookie Equipment: ◦ High-Protein Cookies: Require mixing technology suitable for stickier dough; ◦ Sugar-Free Cookies: Design baking chambers for high-temperature sugar substitutes like allulose.

• Clean Label Production: Independent production lines to avoid cross-contamination (e.g., gluten-free, nut-free products).

Which Market Did The Loyal Biscuit Making Equipment Sold?

Customer Case Of Small Scale Automatic Biscuit Production Line | |

1 | 100KG/H Thai soft biscuit production line for Thailand customer |

2 | 100KG/H small scale biscuit making machine for sale in Uzbekistan |

3 | 100KG/H fully automatic biscuit making machine for sale in Nigeria |

Customer Case Of Industrial Automatic Biscuit Production Line | |

1 | Industrial biscuit making machine fully automatic 100KG/H in Algerian |

2 | 80KG/H industrial fully automatic small scale biscuit making machine for sale in Senegal |

3 | 100KG/H industrial biscuit making machine buy online sold in Russia |

Customer Have Raw Material Case Of Automatic Biscuit Production Line | |

1 | 500KG/H industrial soft biscuit production line for sale in Bolivia |

2 | Mozambique 500KG/H industrial automatic biscuit making machine |

3 | 300KG/H fully automatic automatic biscuit production line for sale in Pakistan |

Reference

The following are five authoritative foreign literature websites in the field of Industrial food machinery:

1. Food Engineering Magazine

Website: https://www.foodengineeringmag.com/

2.Food Processing Magazine

Website: https://www.foodprocessing.com/

3.Journal of Food Engineering

Website:https://www.journals.elsevier.com/journal-of-food-engineering

4. Food Manufacturing Magazine

Website:https://www.foodmanufacturing.com/

5. International Journal of Food Science & Technology

Website:https://onlinelibrary.wiley.com/