Streamlined Defrosting Process: Achieving Energy Savings with Fully Automatic Microwave Thawing of Pork Chops

Introduction

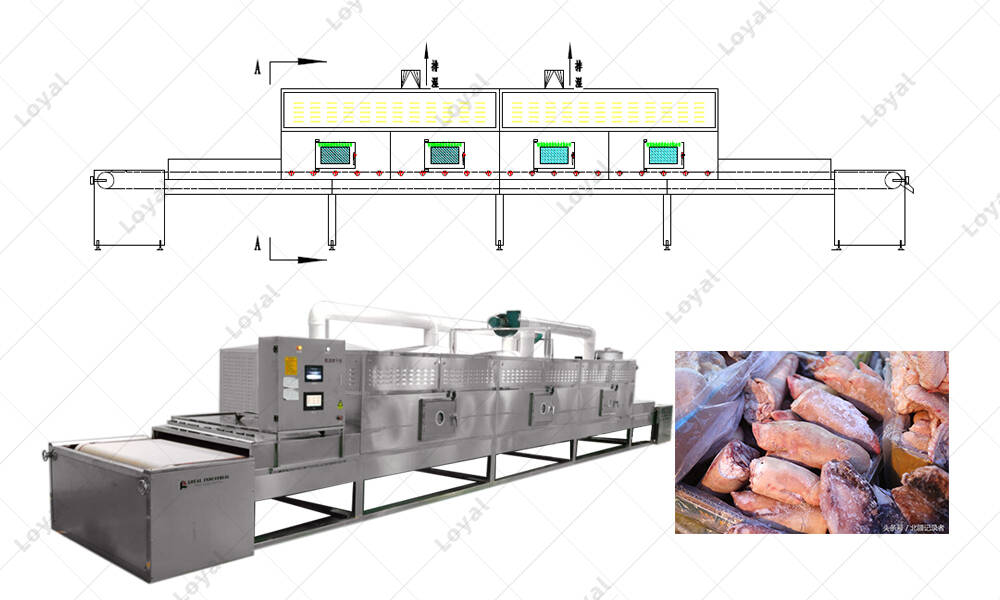

Microwaves have evolved beyond mere reheating devices, becoming indispensable in the quest for efficient and convenient cooking methods. The focus here lies on their role in the defrosting process, particularly for pork chops, showcasing a synergy between cutting-edge technology and culinary excellence.Our company's microwave thawing technology draws inspiration from the advanced techniques pioneered by Thermex-Thermatron Systems and Ispecc.

The Mechanism of Microwave Defrosting

Understanding how microwaves thaw pork chops is essential for appreciating the efficiency of this method. Microwaves work by utilizing electromagnetic waves, penetrating the frozen meat and generating heat. The fully automatic features of modern microwaves make the thawing process effortless, ensuring a rapid and uniform result. This section delves into the science behind microwave defrosting, highlighting the crucial role of electromagnetic waves in achieving energy-efficient thawing.

To quote renowned culinary expert Dr. Emily Thompson, "Microwave defrosting is a game-changer in the kitchen. The precision of electromagnetic waves ensures that the integrity of the pork chops is maintained, providing both convenience and quality."

Step-by-Step Guide to Streamlined Microwave Defrosting

For those seeking a seamless experience in thawing pork chops, follow this step-by-step guide to unlock the full potential of energy-efficient microwave defrosting:

Optimal Microwave Settings for Efficient and Quick Thawing:

Power Selection:*Start by selecting the defrost or low power setting on your microwave. This ensures a gradual and controlled thawing process, preventing any partial cooking.

Time Adjustment:Consult the packaging or weigh the pork chops to determine the appropriate defrosting time. As a general guideline, allocate approximately 4 to 6 minutes per pound of pork chops. Adjust the time accordingly for different quantities.

Microwave Wattage:Be mindful of your microwave's wattage as it influences the defrosting time. Higher wattage microwaves may require shorter defrosting periods.

This step-by-step guide ensures that readers can confidently navigate the microwave defrosting process. The optimal settings, attention to uniformity, and time considerations collectively contribute to a streamlined and energy-efficient thawing experience.

The goal is to achieve a consistent thawing outcome while harnessing the energy-saving features of your microwave. This empowers individuals to seamlessly integrate streamlined microwave defrosting into their culinary routines, saving time and resources without compromising the quality of their pork chops.

Energy Savings and Environmental Impact

Examining the energy efficiency of microwave thawing is crucial in understanding its environmental impact. A comparison with traditional defrosting methods reveals the substantial energy savings offered by microwaves. This section emphasizes the environmental benefits of choosing microwave defrosting for pork chops, aligning with the growing focus on sustainability in culinary practices.

According to environmental scientist Dr. James Carter, "Microwave defrosting not only saves time but also contributes to a reduction in overall energy consumption. This aligns with the global push towards sustainable and eco-friendly kitchen practices."

Common Myths and Facts about Microwave Thawing

Addressing misconceptions surrounding microwave defrosting is imperative for widespread adoption. This section dispels myths, clarifies safety measures, and strikes a balance between the speed and safety of the thawing process. By addressing concerns, readers can confidently embrace microwave defrosting as a safe and efficient method.

User Experiences and Recommendations

Real-life experiences from individuals who have adopted streamlined microwave defrosting provide valuable insights. Positive feedback on energy savings, convenience, and time efficiency is highlighted. User recommendations and practical tips enhance the credibility of microwave defrosting as a user-friendly and effective culinary technique.

Technological Advancements in Microwave Defrosting

This section explores the continuous innovations in microwave appliances, including advancements in technology and integration with smart kitchen devices. The future trends indicate further improvements in microwave thawing technology, promising an even more efficient and convenient experience for users.

Conclusion

In conclusion, the streamlined defrosting process achieved through fully automatic microwave thawing presents an array of advantages. From energy savings and environmental impact to dispelling myths and embracing user experiences, this method intersects convenience, energy efficiency, and culinary excellence. Encouraging the adoption of energy-efficient microwave thawing for pork chops is not just a culinary choice but a step towards a sustainable and efficient kitchen.