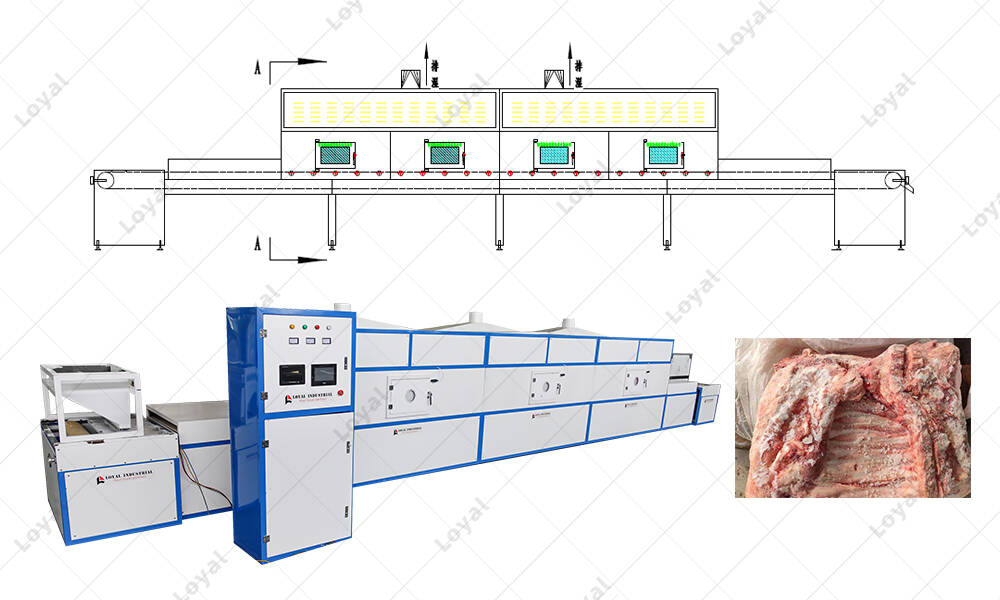

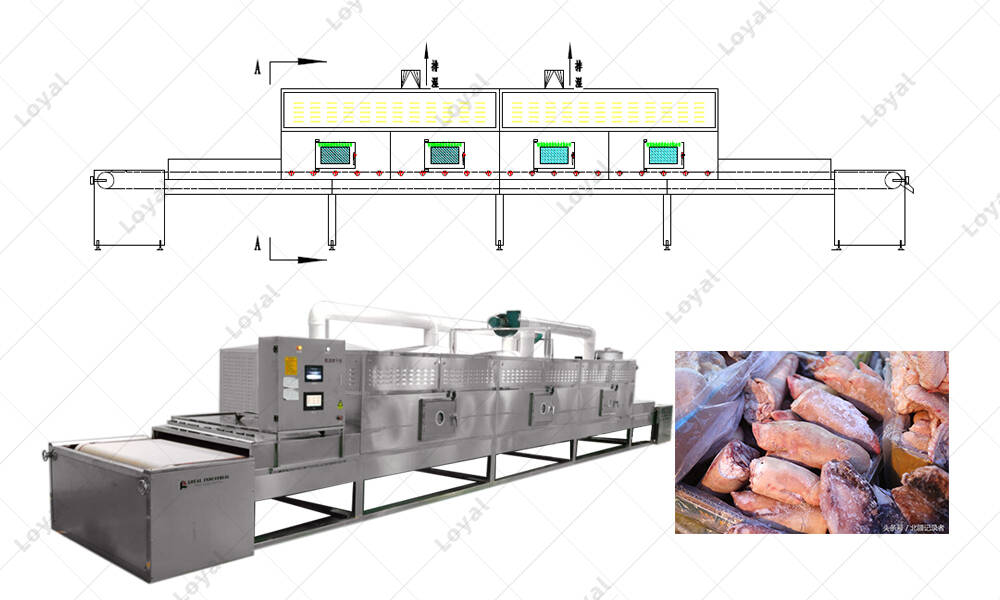

Fully Automatic Microwave Defrost: Effortlessly Thaw Frozen Meat with High Efficiency and Energy Savings

Introduction

This article delves into the groundbreaking concept of Fully Automatic Microwave Defrost, highlighting its transformative impact on the realms of convenience, efficiency, and energy conservation in the intricate process of meat thawing. As we explore this innovative approach, it becomes evident how technology is reshaping culinary practices to align with the demands of modern lifestyles.Our company's microwave thawing technology draws inspiration from the advanced techniques pioneered by Thermex-Thermatron Systems and Ispecc.

The Science Behind Fully Automatic Microwave Defrosting

To comprehend the innovation of Streamlined Microwave Defrosting, we embark on an exploration of the nuanced workings of microwave mechanisms specifically designed for thawing frozen meat. This section intricately details how microwaves function, underscoring the integration of fully automatic features that elevate defrosting into a seamless and effortless experience. The spotlight is on electromagnetic waves, emphasizing their role in achieving precision, efficiency, and energy efficiency in this cutting-edge technology.

Unmatched Efficiency: Exploring the Speed and Precision of Fully Automatic Microwave Defrost

In the pursuit of efficiency, the Fully Automatic Microwave Defrost method stands out as a beacon of innovation. Traditional thawing methods often demand significant time investments, leading to delays in meal preparation. In contrast, the speed achieved through fully automatic features ensures that the thawing process is not only swift but also precise. This precision extends to different types of frozen meat, acknowledging the diverse culinary needs of users.

Real-life examples serve as compelling narratives, illustrating the transformative impact of Fully Automatic Microwave Defrost. Users share their experiences of effortlessly thawing various cuts of frozen meat in record time, enabling them to proceed with cooking without the lengthy waiting periods associated with conventional methods. These narratives not only highlight the efficiency of the technology but also emphasize the practical convenience it introduces into daily culinary practices.

Energy Savings through Microwave Defrosting

An indispensable aspect of this revolutionary approach is its contribution to energy conservation. This section meticulously evaluates the energy efficiency of Fully Automatic Microwave Meat Thawing, drawing insightful comparisons with conventional thawing techniques. The environmental impact and the practice's alignment with sustainable culinary habits take center stage, echoing global efforts toward eco-friendly practices.

The energy efficiency of Fully Automatic Microwave Defrost goes beyond the immediate convenience it offers. By utilizing advanced technologies and fully automatic features, this method optimizes energy consumption during the thawing process. The comparative assessment reveals a reduction in energy usage compared to traditional thawing methods, underlining the method's commitment to sustainability.

As the culinary landscape increasingly emphasizes eco-friendly practices, the article demonstrates how Fully Automatic Microwave Defrost aligns with these principles. It not only presents users with a convenient and efficient thawing solution but also contributes to broader sustainability goals by minimizing energy consumption. This intersection of efficiency and environmental consciousness positions the technology as a pioneering force in modern culinary practices.

Step-by-Step Guide to Fully Automatic Microwave Defrosting

For those eager to embrace this culinary breakthrough, a comprehensive step-by-step guide is provided. This detailed roadmap navigates the optimization of microwave settings for various types of frozen meat, ensuring a safe and uniform thawing process through the utilization of fully automatic features. Time considerations tailored to different quantities of frozen meat impart practical insights, empowering users to make the most of this cutting-edge technology in their culinary pursuits.

Embarking on the journey of Fully Automatic Microwave Defrosting requires a nuanced understanding of microwave settings. This step-by-step guide meticulously details the optimization process for different types of frozen meat, ensuring users unlock the full potential of their microwave appliances. The inclusion of fully automatic features simplifies the thawing process, making it accessible to both novice and experienced cooks.

Practical insights into time considerations cater to the diverse needs of users. Whether dealing with a small quantity for an individual meal or a larger quantity for a family gathering, the guide offers tailored recommendations. These insights empower users to navigate the thawing process efficiently, ensuring a seamless experience that aligns with the fast-paced demands of contemporary lifestyles.

Addressing Common Myths and Safety Measures

Dispelling myths surrounding microwave defrosting is crucial for the widespread adoption of this advanced technique. This section is dedicated to clarifying safety measures, ensuring a secure thawing experience. The delicate balance between speed and safety takes center stage, with a comprehensive focus on how fully automatic features contribute to a reliable and efficient thawing process, debunking misconceptions along the way.

As with any innovative culinary method, Fully Automatic Microwave Defrost has faced its share of myths and misconceptions. This section systematically addresses these concerns, providing evidence-backed explanations to instill confidence in users. Safety measures are a paramount consideration, and the article emphasizes the technology's design to prioritize secure thawing.

The delicate balance between speed and safety is carefully elucidated, assuring users that the efficiency of Fully Automatic Microwave Defrost does not compromise the integrity of the thawing process. By addressing common myths and highlighting safety measures, this section aims to build trust in the technology, paving the way for broader acceptance and integration into daily culinary practices.

User Testimonials: Real Experiences with Fully Automatic Microwave Defrost

Real voices from users serve as a testament to the positive impact of Fully Automatic Microwave Defrost. Their testimonials provide firsthand insight into the convenience and time efficiency achieved, offering valuable recommendations. Additionally, users share practical tips and tricks, creating a community-driven space to enhance the overall microwave thawing experience.

Future Trends in Microwave Defrosting Technology

As technology evolves, the future of microwave defrosting unfolds. This section ventures into ongoing innovations in microwave appliances, exploring their integration with smart kitchen devices for enhanced control. Predictions for future developments hint at even faster and more efficient thawing methods, ensuring that the kitchen remains at the forefront of technological advancements.

Conclusion

In conclusion, the article encapsulates the Fully Automatic Microwave Defrosting Experience, advocating for the adoption of energy-efficient practices in culinary environments. It leaves the reader with final thoughts, fostering an appreciation for the seamless intersection of convenience, efficiency, and energy conservation in the evolving landscape of culinary excellence.