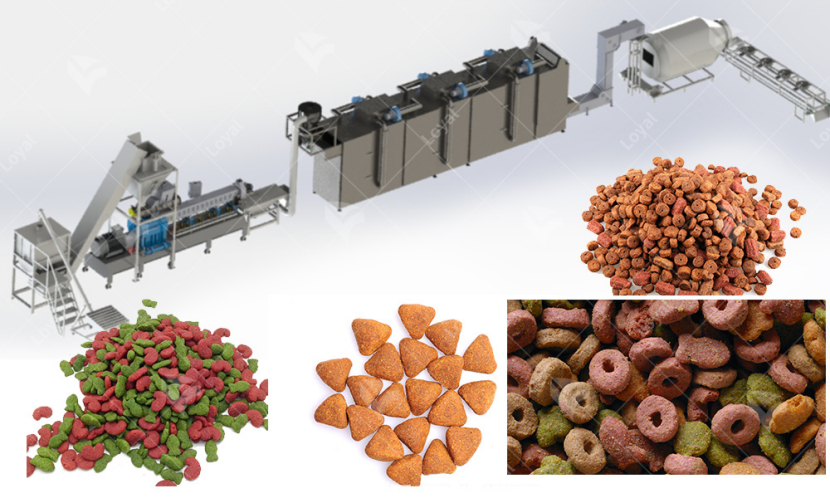

Professional Pet And Animal Food Making Machine With Custom-Design Service

Introduction of Pet And Animal Food Making Machine:

We improve the palatability of dog food, dry dog food, puffed to become crispy, pet dogs in the process of biting off and swallowing, have a better taste and clean mouth teeth role.And change and improve the nutritional value of dog food, many nutrients are required to be cooked and puffed to become nutritious, otherwise not only will not bring effective nutrition to the pet dog, but will cause diarrhea, vomiting and other indications.At the same time to improve the digestion and absorption rate of dog food, puffed dog food pet dog absorption up more comprehensive and perfect, there is even a "double puffing" process, the purpose is to make the pet dog more perfect to absorb all the nutrients in the dog food.And change the content of different nutritional indicators of dog food, such as reducing water can improve the shelf life of dog food, more convenient for pet owners to store and feed at any time, anywhere, and safe, and convenient; And change the density of dog food, extrusion granulation, puffing can also increase the bulk density of dog food, easy to purchase and transport.Finally, the puffing process is also a high-temperature and high-pressure process, can kill a variety of mold, Salmonella and other harmful substances, to improve the safety of dog food, health.

The whole pet food production line can automatically complete the production from mixer,screw conveyor,twin screw extruder,air conveyor, multi-layer oven,flavoring line to the finished product.

Details of the production line:

| Production capacity | 120-2000kg/h |

| Electricity supply | Customised according to your local electricity situation. |

| Machine details | 1.Stainless steel:201, 304, 316, on request. 2.Electrical components can be ABB, Delta, Fuji, Siemens, famous brands. |

| Certificates | CE,GOST,TUV,BV,SGS |

Flow chart of Pet Food processing line:

Mixer-Screw Conveyor-Twin Screw Extruder-Air Conveyor-Multi Layer Oven-Flavoring Line

Features of the Pet Food processing line:

1.Productivity:automated system for controlled and stable production on a continuous basis, easy and quick product change, automatic start-up, simple cleaning and maintenance procedures.

2.Economical: low investment, quick results.

3.Environmental protection: moderate output and energy saving.

4.Intelligent control system: PLC control of production to ensure optimum process parameters for each recipe.

5.Automatic lubrication system can reduce power consumption and prolong service life.

Parameters of the Pet Food Production Line:

Model | Installed Power (KW) | Power Consumption (kw) | Capacity (kg/h) | Dimension (m) |

| LY65Pet Food Production Line | 70 | 45 | 120-150 | 20000*1200*2200mm |

LY70Pet Food Production Line | 105 | 85 | 200-250 | 23000*1500*2200mm |

LY85 Pet Food Production Line | 160 | 130 | 300-500 | 25000*2500*2300mm |

LY95Pet Food Production Line | 220 | 154 | 800-1000 | 28000*2500*3500mm |

KING135Pet Food Production Line | 241.2 | 180.9 | 1500-2000 | 45000*2000*3000mm |