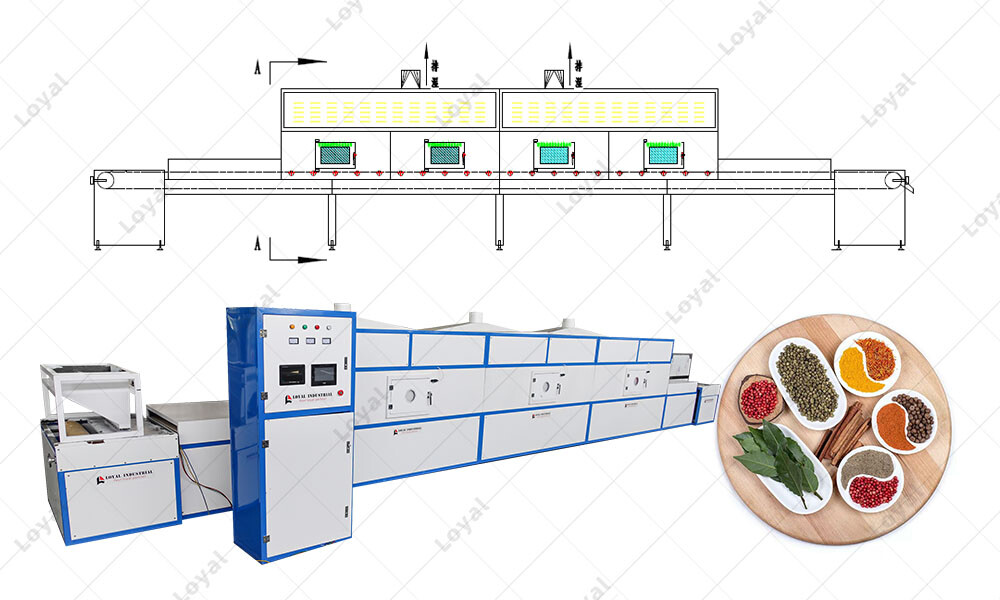

Precision Sterilization: Full Automatic Microwave Spices Sterilizer Machine for Enhanced Quality

Introduction

Our company leverages cutting-edge technologies from Ispecc and Püschner to develop a state-of-the-art microwave sterilization technique. By drawing inspiration from the advanced methodologies employed by Ispecc and Püschner, we have successfully integrated their innovative approaches into our manufacturing process. This collaborative effort ensures that our microwave sterilization technology meets the highest industry standards, providing an effective and efficient solution for eliminating harmful microorganisms. Through continuous refinement and adaptation of these proven techniques, our company remains at the forefront of technological advancements in the field, delivering products that prioritize both safety and quality.

Advantages of Full Automation

Explanation of Full Automation Features in Microwave Spices Sterilizer Machine:

The Microwave Spices Sterilizer Machine operates with full automation, integrating smart systems to streamline the sterilization process. Automated loading, unloading, and monitoring contribute to a consistent and controlled environment, ensuring precision in spice treatment.

Benefits of Automated Processes in Enhancing Spice Quality:

Full automation goes beyond operational efficiency; it plays a pivotal role in enhancing spice quality. By minimizing human intervention, the risk of contamination is significantly reduced, leading to higher-quality spice products.

Comparison with Traditional Spice Sterilization Methods:

A comparative analysis will highlight the superiority of Microwave Spices Sterilizer Machine over traditional methods. The benefits of automated processes in terms of quality, efficiency, and precision will be emphasized.

Precision Sterilization Technology

In-depth Analysis of Microwave Technology in Sterilizing Spices:

Microwave technology offers a unique approach to spice sterilization. This section will provide a detailed examination of how microwaves penetrate spices, effectively eliminating pathogens while preserving flavor and aroma.

Impact on Maintaining Spice Flavor and Aroma:

The precision sterilization techniques employed by the Microwave Spices Sterilizer Machine ensure that the natural flavors and aromas of spices remain intact. Scientific insights into the interaction between microwaves and spices will be explored.

Scientific Insights into Precision Sterilization Techniques:

Esteemed experts in the field will be cited to provide scientific insights into the precision sterilization techniques employed by the Microwave Spices Sterilizer Machine, establishing the credibility of the technology.

Operational Efficiency and High Quality

Detailed Examination of Operational Efficiency in Microwave Spices Sterilizer Machine:

This section will scrutinize the operational efficiency of the Microwave Spices Sterilizer Machine, exploring factors such as processing speed, energy utilization, and overall system performance. Operational efficiency is a key contributor to maintaining high-quality spice products consistently.

How Full Automation Contributes to Consistent High-Quality Spice Products:

The correlation between full automation and the consistent production of high-quality spice products will be elaborated upon. By minimizing variations in the sterilization process, full automation ensures uniform quality across batches.

Real-world Examples Showcasing the Relationship Between Efficiency and Quality:

Real-world case studies and testimonials from spice manufacturers using Microwave Spices Sterilizer Machines will be presented. These examples will highlight the tangible relationship between operational efficiency and the delivery of superior-quality spice products.

Industry Applications and Future Developments

Exploring Diverse Applications of Microwave Spices Sterilizer Machine Across Industries:

The versatility of Microwave Spices Sterilizer Machine extends beyond spice manufacturers. This section will explore how the technology is applied in various industries, showcasing its adaptability and effectiveness

Industries Benefiting from Full Automation and Enhanced Spice Quality:

Insights into industries reaping the benefits of full automation in spice sterilization will be provided. The emphasis will be on how the Microwave Spices Sterilizer Machine elevates spice quality and meets the stringent demands of different sectors.

Future Trends and Innovations in Microwave Spice Sterilization Technologies:

To maintain a forward-looking perspective, this part will discuss emerging trends and innovations in microwave spice sterilization technologies. Expert opinions and industry forecasts will be incorporated to provide insights into the future landscape of spice processing.

Environmental Considerations and Energy Efficiency

Discussion on the Green Aspects of Microwave Spice Sterilization:

This section will delve into the environmentally friendly features of Microwave Spice Sterilization. The reduced use of resources and minimal environmental impact will be discussed, emphasizing the machine's contribution to sustainable and eco-friendly spice processing.

Measures Taken for Energy Efficiency and Sustainability in Spice Processing:

Detailed insights into the energy efficiency measures implemented in Microwave Spice Sterilizer Machine will be presented. From the use of energy-saving components to innovative technologies, the article will showcase how the machine aligns with sustainability practices in spice processing.

Comparative Environmental Analysis with Other Spice Sterilization Methods:

A comparative analysis will be conducted to highlight the environmental advantages of Microwave Spice Sterilization over traditional methods. This section will provide a comprehensive understanding of the ecological benefits, backed by scientific data and authoritative opinions.

Challenges and Solutions

Identification of Potential Challenges in Microwave Spice Sterilization:

Anticipating challenges is crucial for effective implementation. This part will identify potential challenges in Microwave Spice Sterilization, including technical limitations, regulatory considerations, and industry adaptation, setting the stage for the subsequent solutions.

Strategies and Solutions for Overcoming Sterilization Hurdles:

Viable strategies and solutions will be presented to address the identified challenges. Drawing on industry best practices and expert opinions, this section will provide actionable insights for overcoming hurdles and ensuring the smooth operation of Microwave Spice Sterilizer Machines.

Continuous Improvement in Machine Design and Functionality:

Highlighting the commitment to excellence, this part will explore how manufacturers actively engage in refining the design and functionality of Microwave Spice Sterilizer Machines. Continuous improvement is key to addressing challenges and meeting evolving industry demands.

Conclusion

In conclusion, the journey through the world of precision sterilization with Full Automatic Microwave Spices Sterilizer Machines has unveiled a transformative solution for the spice processing industry. The amalgamation of full automation, advanced technology, and a commitment to quality has positioned these machines as a cornerstone in elevating spice standards.

Looking ahead, the future outlook for spice processing technologies is promising. Continuous improvements in machine design and functionality, coupled with emerging trends and innovations, underscore the dynamic nature of this field. As industry stakeholders, embracing advanced sterilization technologies, including Microwave Spice Sterilizer Machines, becomes not just an option but a strategic imperative.

In conclusion, there is a clear call to action for the spice industry: adopt and integrate Full Automatic Microwave Spices Sterilizer Machines to ensure not only the precision and efficiency required but also to contribute to environmentally sustainable and energy-efficient spice processing practices.