Optimal Thawing Efficiency: Fully Automatic Microwave Defrosting for Frozen Meat with Enhanced Energy Savings

Introduction

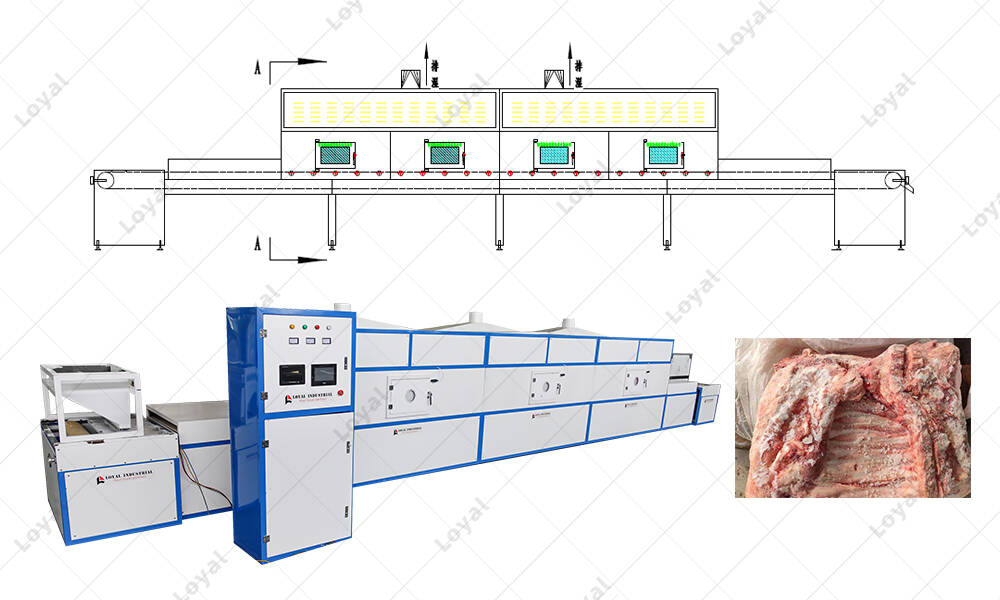

In the realm of modern culinary practices, achieving optimal thawing efficiency is paramount. The demand for energy-efficient solutions in microwave defrosting has witnessed a notable surge. This introduction sets the stage for exploring the revolutionary landscape of fully automatic microwave defrosting, presenting a paradigm shift in the efficiency of thawing frozen meat with enhanced energy savings.Our company's microwave thawing technology draws inspiration from the advanced techniques pioneered by Thermex-Thermatron Systems and Ispecc.

The Science Behind Fully Automatic Microwave Defrosting

To comprehend the innovation of fully automatic microwave defrosting, it's essential to delve into the intricate science behind it. This section provides a comprehensive explanation of the microwave mechanisms involved in thawing frozen meat. We explore how the integration of fully automatic features contributes to an effortless and precise defrosting experience. At the core of this process is the utilization of electromagnetic waves, ensuring not only optimal efficiency but also enhanced energy savings.

Unmatched Efficiency: Exploring Speed and Precision in Microwave Defrosting

At the heart of this culinary evolution is an unwavering commitment to unparalleled efficiency. A detailed comparative analysis unveils the speed advantages of fully automatic defrosting compared to traditional methods. Beyond speed, we delve into the precision applied to thaw different types of frozen meat. Real-life examples emphasize the unmatched efficiency and convenience that fully automatic microwave defrosting brings to the culinary experience.

Enhanced Energy Savings through Fully Automatic Microwave Defrosting

This section critically evaluates the advanced energy efficiency achieved through fully automatic meat thawing in the microwave. By comparing energy consumption with conventional thawing techniques, we highlight the environmental impact and contributions to sustainable culinary practices. The emphasis is on how adopting fully automatic solutions can lead to a significant reduction in energy consumption.

Step-by-Step Guide to Optimal Fully Automatic Microwave Defrosting

For those eager to embrace this culinary breakthrough, a comprehensive step-by-step guide is presented. This roadmap navigates the optimization of microwave settings for various types of frozen meat, ensuring a safe and uniform thawing process through the utilization of fully automatic features. Tailored time considerations for different quantities of frozen meat provide practical insights, empowering users to make the most of this cutting-edge technology in their culinary pursuits.

Addressing Common Myths and Ensuring Safety

Dispelling myths surrounding microwave defrosting is crucial for the widespread adoption of this advanced technique. This section is dedicated to clarifying safety measures, ensuring a secure thawing experience. The delicate balance between speed and safety takes center stage, with a comprehensive focus on how fully automatic features contribute to a reliable and efficient thawing process, debunking misconceptions along the way.

User Testimonials: Real Experiences with Fully Automatic Microwave Defrost

User testimonials showcase firsthand experiences with fully automatic microwave defrosting. Positive feedback emphasizes the convenience and time efficiency gained through this innovative approach. Users share their recommendations for optimizing energy savings and provide valuable tips and tricks for enhancing the overall microwave thawing experience.

Future Trends in Microwave Defrosting Technology

As we peer into the future of microwave defrosting technology, the ongoing innovations in microwave appliances promise to redefine our culinary landscape. The evolution of this technology goes beyond mere efficiency; it encompasses a holistic approach towards convenience and control.

The future trends in microwave defrosting technology are poised to bring about transformative changes. With a focus on integration, precision, energy efficiency, and safety, these innovations aim to provide users with unparalleled control over the thawing process, making it not only faster but also more tailored to individual preferences and environmental considerations. As we embrace these advancements, the kitchen of the future holds the promise of even greater culinary convenience.

Conclusion

In conclusion, we recapitulate the optimal thawing efficiency achieved through fully automatic microwave defrosting. The call to adopt energy-efficient practices in culinary environments is reinforced, and final thoughts reflect on the seamless intersection of convenience, efficiency, and energy conservation brought about by this revolutionary technology.

Common Questions about Defrosting Frozen Meat in Microwave

Is defrosting meat in a microwave safe?

Absolutely. Fully automatic solutions for defrosting frozen meat in a microwave are designed with safety as a top priority. The process is carefully calibrated to ensure even and controlled thawing, minimizing any potential safety risks. It's crucial to follow the manufacturer's guidelines and recommendations for a secure thawing experience.

How does fully automatic defrosting differ from traditional methods?

Fully automatic defrosting in a microwave stands out for its speed, precision, and efficiency compared to traditional methods. The integrated features optimize the thawing process, ensuring that different types of frozen meat are thawed uniformly and without the drawbacks associated with conventional methods.

Can I defrost various types of frozen meat using the same settings?

Yes, one of the advantages of fully automatic solutions is their adaptability. These systems are designed to accommodate various types of frozen meat, from poultry to beef, with optimized settings. The user-friendly interface allows you to select the type of meat, and the microwave adjusts the settings accordingly for safe and efficient defrosting.

How does fully automatic defrosting contribute to energy savings?

Fully automatic defrosting minimizes energy consumption by precisely tailoring the thawing process to the specific needs of the frozen meat. The efficient use of electromagnetic waves and controlled settings ensures that energy is used only where and when necessary, contributing to overall energy savings in the culinary process.