Fully Automatic Microwave Defrost Machine: Streamlining Pasta Production

Introduction

In the fast-paced world of food production, the efficiency and precision of defrosting processes play a crucial role. This article explores the revolutionary advancements in the field, particularly with the introduction of the Fully Automatic Microwave Defrost Machine. As we delve into the intricacies of microwave defrosting, understanding its significance in enhancing overall food production efficiency becomes paramount.Our company's microwave thawing technology draws inspiration from the advanced techniques pioneered by Thermex-Thermatron Systems and Ispecc.

Overview of Microwave Defrosting

Microwave defrosting has evolved into a cornerstone technology in the food industry. It leverages electromagnetic waves to thaw frozen food rapidly, ensuring a seamless production flow. The Fully Automatic Microwave Defrost Machine takes this technology to new heights, promising not only speed but also a level of automation that streamlines the entire defrosting process.

Importance of Efficient Defrosting in Food Production

Efficient defrosting is more than just a time-saving measure; it directly impacts the quality and safety of the final food product. In the competitive landscape of food manufacturing, any delay or compromise in defrosting can lead to significant setbacks. The Fully Automatic Microwave Defrost Machine addresses these challenges, aiming to elevate food production standards.

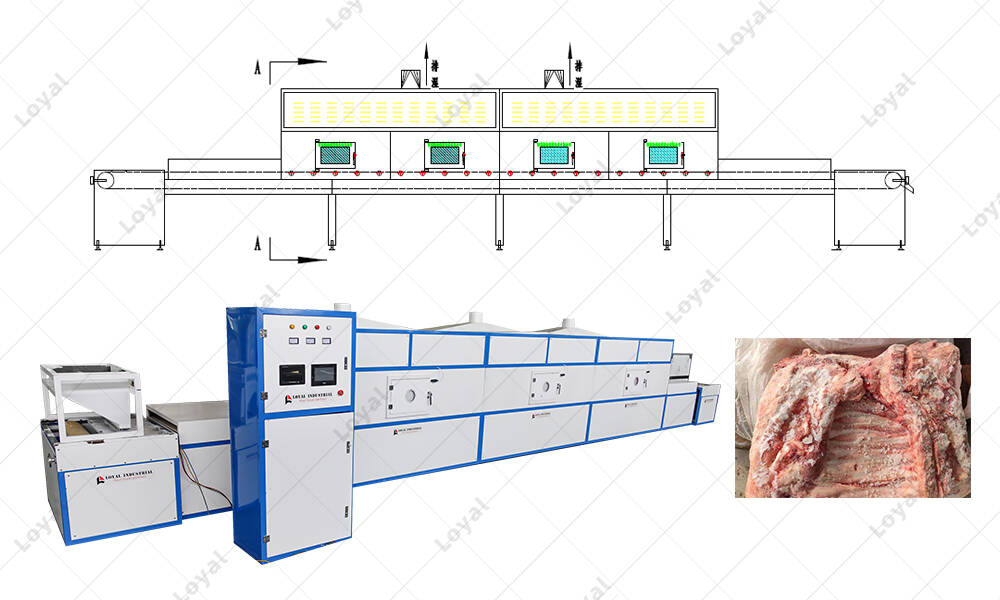

Introduction to Fully Automatic Microwave Defrost Machine

At the heart of this article is the introduction of the Fully Automatic Microwave Defrost Machine. This cutting-edge machinery integrates rapid defrosting technology, precise control systems, and an energy-efficient design. Before delving into its features, let's explore the fundamental advantages that come with adopting such a revolutionary system.

Key Features of the Microwave Defrost Machine

As we shift our focus to the core features of the Fully Automatic Microwave Defrost Machine, it becomes evident how these attributes contribute to the streamlining of pasta production.

Boldly embracing rapid defrosting technology, this machine ensures that the pasta production line experiences minimal downtime. The enhanced speed doesn't compromise the quality of defrosting, guaranteeing that each ingredient is thawed uniformly and efficiently.

The Fully Automatic Microwave Defrost Machine boasts a state-of-the-art control and monitoring system. This level of precision allows food manufacturers to tailor the defrosting process according to specific requirements. The meticulous control ensures that each batch of pasta ingredients undergoes optimal defrosting conditions.

In an era where sustainability is paramount, the energy-efficient design of this machine aligns with global environmental goals. By minimizing energy consumption during the defrosting process, the Fully Automatic Microwave Defrost Machine contributes to a more eco-friendly approach to food production.

Beyond its application in pasta production, the machine's versatility shines through in its ability to defrost various food types. This adaptability adds a layer of flexibility for manufacturers, allowing them to explore diverse product lines without compromising on efficiency.

Advantages of Using Fully Automatic Microwave Defrost Machine

Now, let's delve into the concrete advantages that the Fully Automatic Microwave Defrost Machine brings to the table, transforming the landscape of food production.

The integration of rapid defrosting technology translates directly to improved production efficiency. With reduced defrosting times, the overall production timeline experiences a significant boost. This efficiency not only accelerates output but also allows for better resource allocation within the manufacturing process.

Efficient defrosting is not just about speed; it's about ensuring the safety and quality of the final food product. The Fully Automatic Microwave Defrost Machine excels in maintaining the integrity of ingredients, preserving their texture, flavor, and nutritional value. This commitment to quality resonates with both manufacturers and consumers alike.

Beyond the immediate advantages, the cost-saving aspect of adopting this technology becomes apparent. The streamlined production process, coupled with energy-efficient design, contributes to a reduction in operational costs. As sustainability and cost-effectiveness become central themes in food production, the Fully Automatic Microwave Defrost Machine emerges as a strategic investment.

With a solid understanding of the machine's key features and advantages, we now explore its seamless integration into the pasta production process.

Pasta production demands precision at every stage, and defrosting is no exception. The Fully Automatic Microwave Defrost Machine aligns perfectly with the intricacies of pasta manufacturing. Its rapid technology ensures that frozen ingredients, crucial in pasta recipes, are swiftly prepared for the subsequent production steps.

The impact on the production timeline is noteworthy. By significantly reducing the time required for defrosting, the machine contributes to an accelerated pasta production cycle. This not only meets market demands more efficiently but also provides manufacturers with a competitive edge.

Quality enhancement is a natural byproduct of efficient defrosting. The uniform thawing achieved by the Fully Automatic Microwave Defrost Machine reflects directly in the quality of the pasta produced. Consistency becomes a hallmark, ensuring that each batch meets the highest standards set by discerning consumers.

Case Studies

To substantiate the practical benefits of the Fully Automatic Microwave Defrost Machine, let's examine real-world case studies that highlight successful implementations in pasta factories.

Pasta factories adopting this innovative defrosting technology have reported remarkable improvements in their overall production processes. Case studies reveal a substantial reduction in defrosting time, leading to increased operational efficiency. Manufacturers note a positive impact on the quality of their pasta products, further establishing the machine's efficacy.

The tangible outcomes extend beyond mere efficiency. Pasta factories leveraging the Fully Automatic Microwave Defrost Machine report a noticeable increase in throughput and yield. This not only translates to higher profits but also positions these manufacturers as industry leaders committed to embracing technological advancements.

Challenges and Solutions

While the Fully Automatic Microwave Defrost Machine presents a paradigm shift in food production, addressing potential challenges is essential for a comprehensive understanding.

Acknowledging the nuanced nature of food manufacturing, the article delves into potential challenges associated with microwave defrosting. Whether it's uneven thawing or concerns about texture alterations, the Fully Automatic Microwave Defrost Machine is designed with solutions that mitigate these challenges effectively.

To ensure the sustained performance of the machine, proper maintenance practices and troubleshooting protocols are imperative. This section offers insights into best practices for maintaining the Fully Automatic Microwave Defrost Machine, emphasizing the importance of regular checks and prompt issue resolution.

Future Trends in Microwave Defrost Technology

As the food industry continually evolves, we turn our gaze to the future trends in microwave defrost technology, exploring potential innovations and industry developments.

Ongoing research in microwave defrosting technology promises further breakthroughs. This section provides a glimpse into the cutting-edge innovations that researchers are exploring, hinting at advancements that may redefine the landscape of food production.

Conclusion

The Fully Automatic Microwave Defrost Machine emerges as a game-changer in the realm of food production, specifically in streamlining pasta manufacturing. The journey through the intricacies of microwave defrosting, coupled with the machine's key features and advantages, paints a vivid picture of its transformative impact on the industry.

In essence, the Fully Automatic Microwave Defrost Machine not only addresses current challenges but also positions itself as a catalyst for future advancements. As food production strives for efficiency, quality, and sustainability, this innovative technology stands at the forefront, ready to redefine the way we approach defrosting processes in the ever-evolving world of pasta production and beyond.